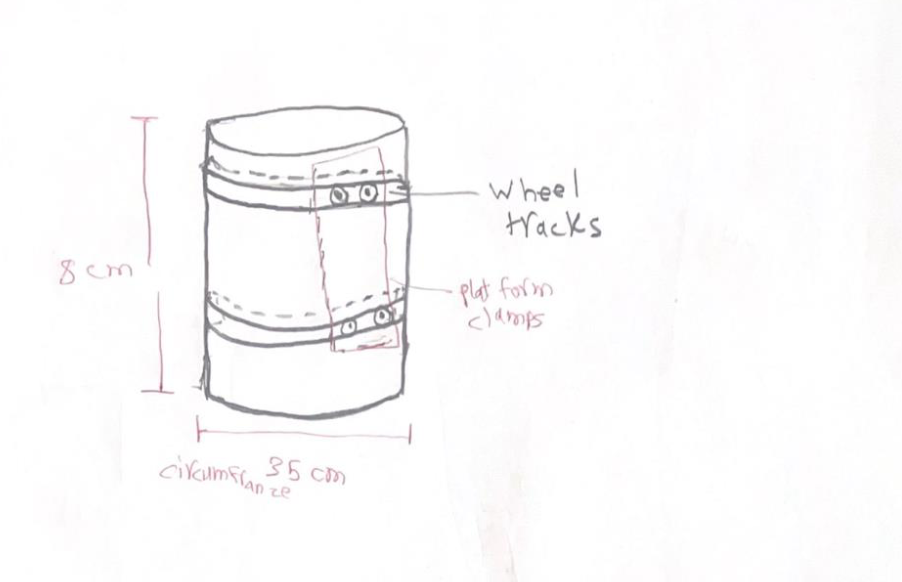

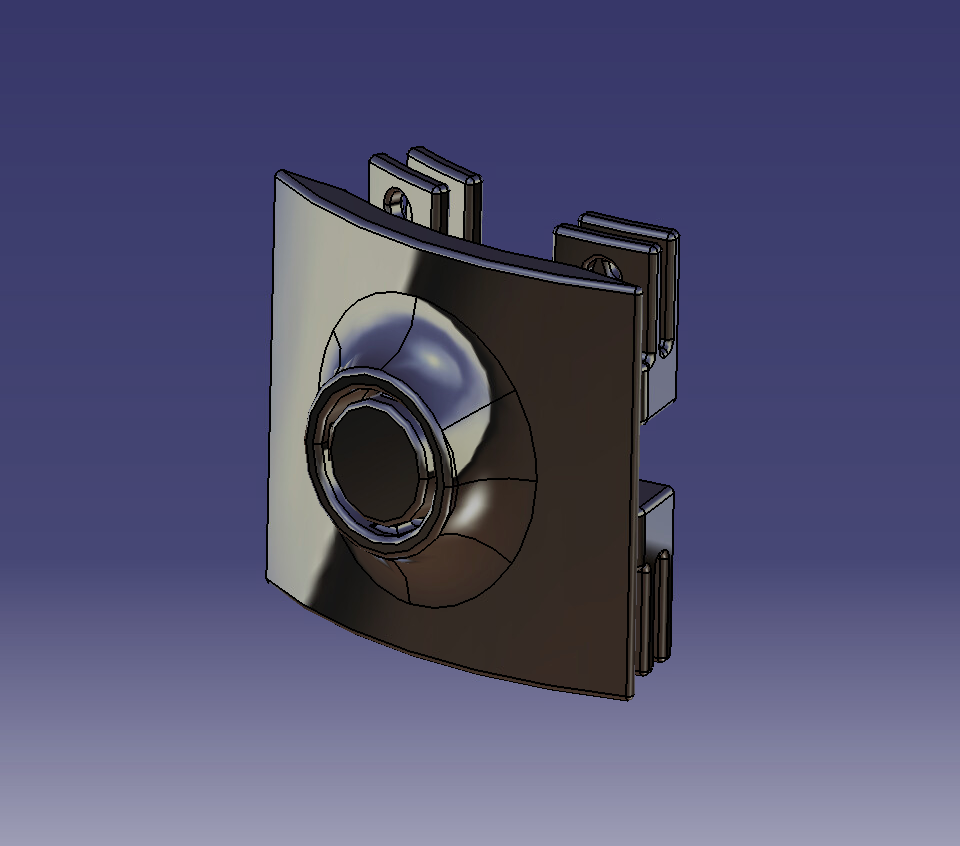

This water bottle holder design enables attachment to various surfaces, offering

convenient placement near a desk or bed. Equipped with adjustable clamps, it securely

fastens to surfaces, with the ability to rotate between horizontal and vertical orientations to

accommodate diverse settings. Additionally, the holder is expandable to accommodate

bottles of varying sizes.

convenient placement near a desk or bed. Equipped with adjustable clamps, it securely

fastens to surfaces, with the ability to rotate between horizontal and vertical orientations to

accommodate diverse settings. Additionally, the holder is expandable to accommodate

bottles of varying sizes.

Design process

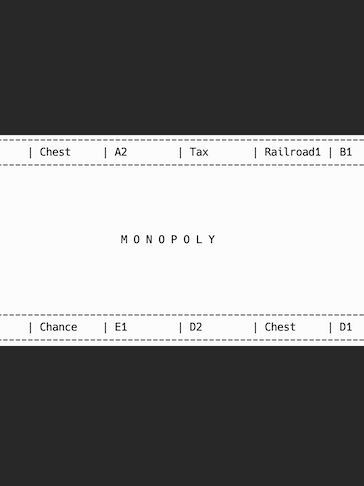

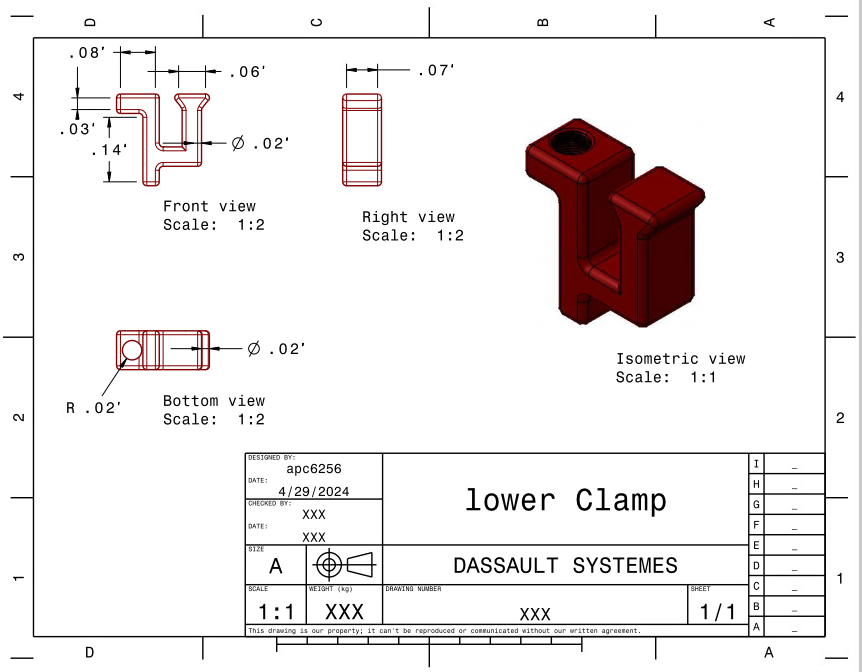

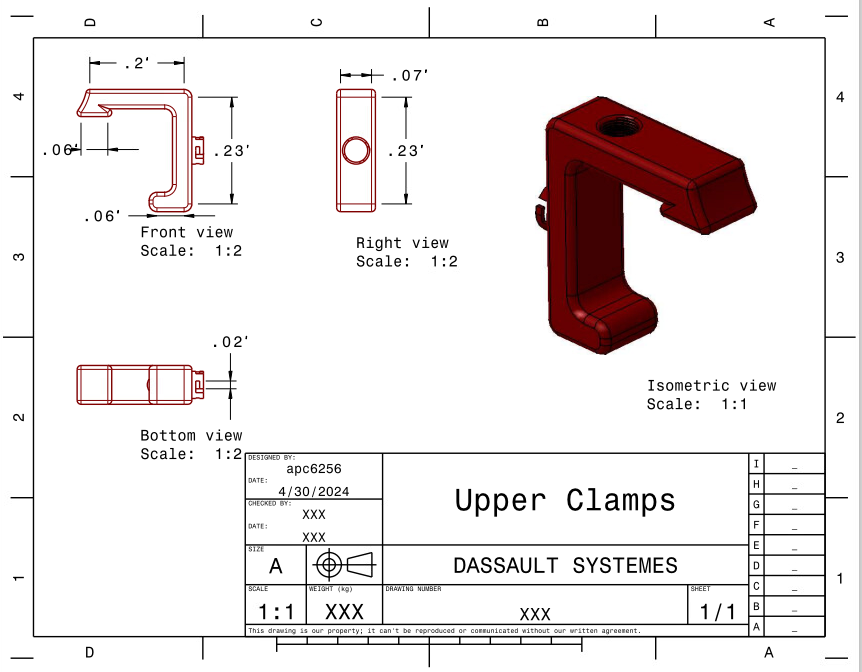

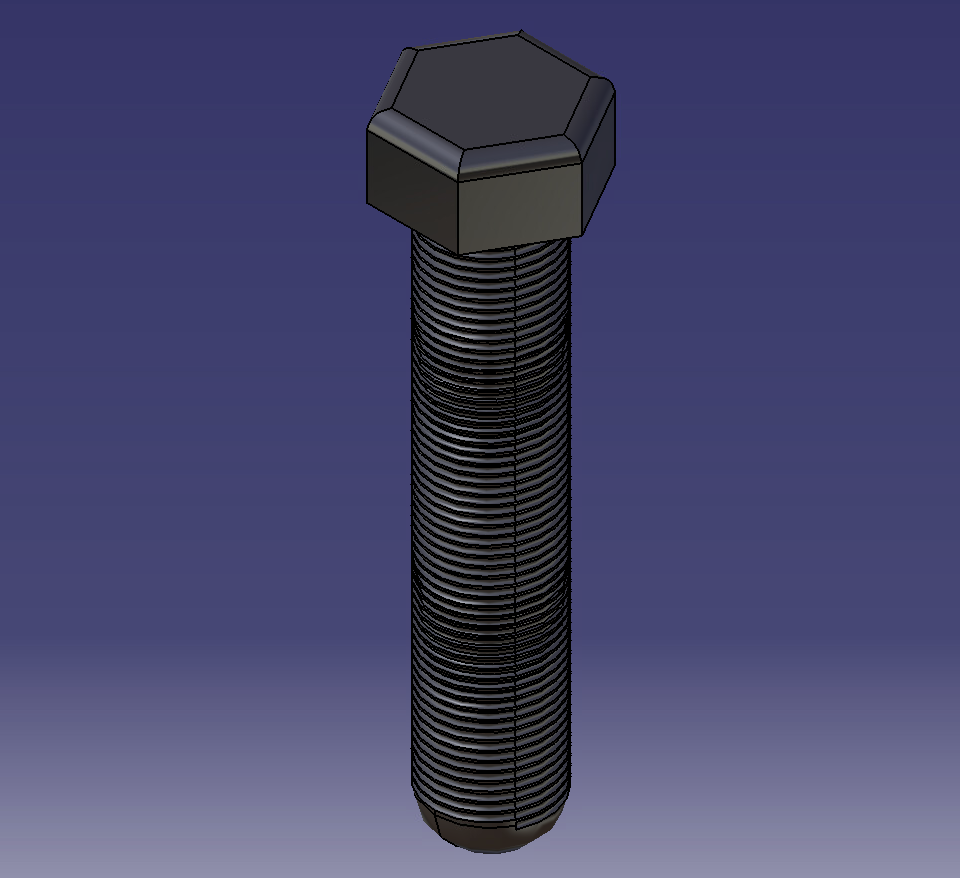

The design process for this project rely on various Catia features. For instance,

the creation of the screw will utilize the helix curve definition to establish the screwing part,

ensuring it follows a specific profile. The hole feature will be employed in the clamps to

accommodate the screw, utilizing a helix curve for precise fitting. The clamps themselves

will be relatively straightforward to create, utilizing the pad and pocket features for the

sketches. Generative sketch design will be employed for efficient creation.

the creation of the screw will utilize the helix curve definition to establish the screwing part,

ensuring it follows a specific profile. The hole feature will be employed in the clamps to

accommodate the screw, utilizing a helix curve for precise fitting. The clamps themselves

will be relatively straightforward to create, utilizing the pad and pocket features for the

sketches. Generative sketch design will be employed for efficient creation.

Determining the requirements involves simplifying the functionality needed. Firstly, the

bottle holder must withstand the weight of a water bottle without breaking. It should

securely attach to both vertical and horizontal surfaces, with reinforced connection points

between clamps and the bottle to support weight. An adjustable design is necessary to

accommodate various bottle sizes.

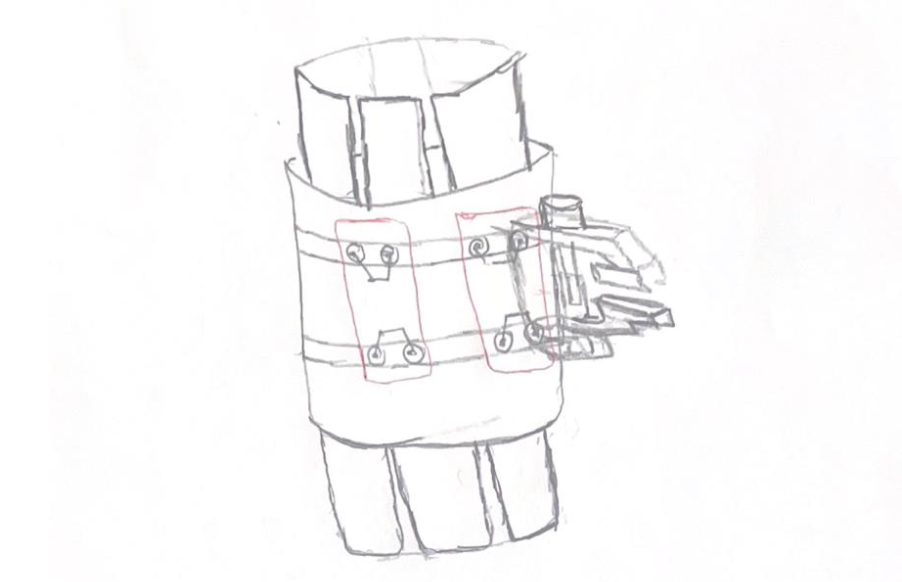

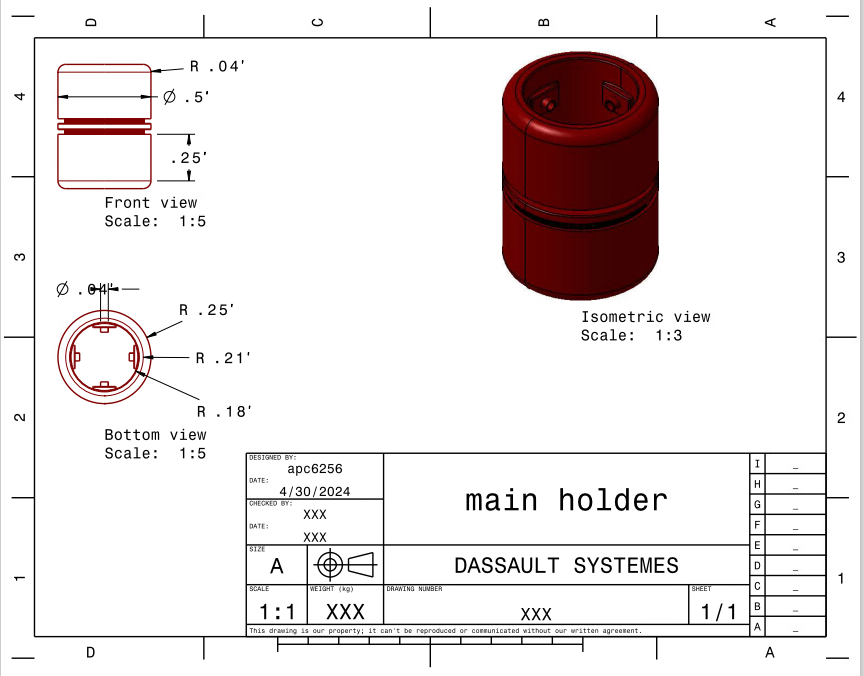

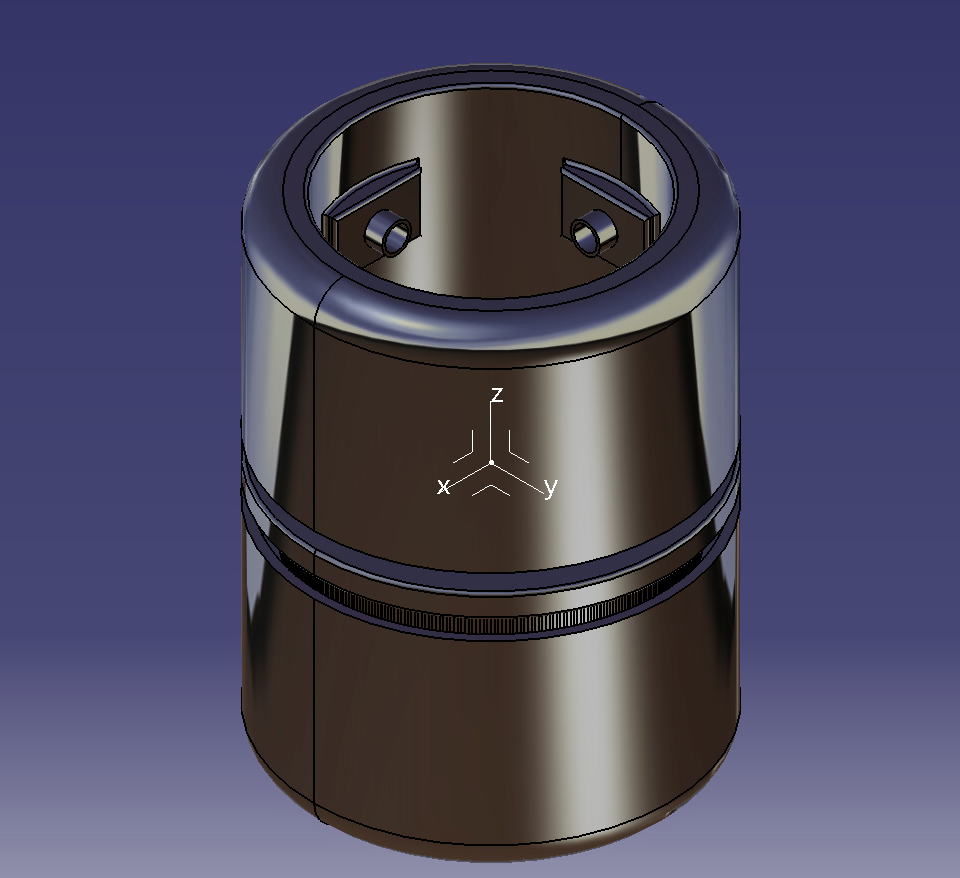

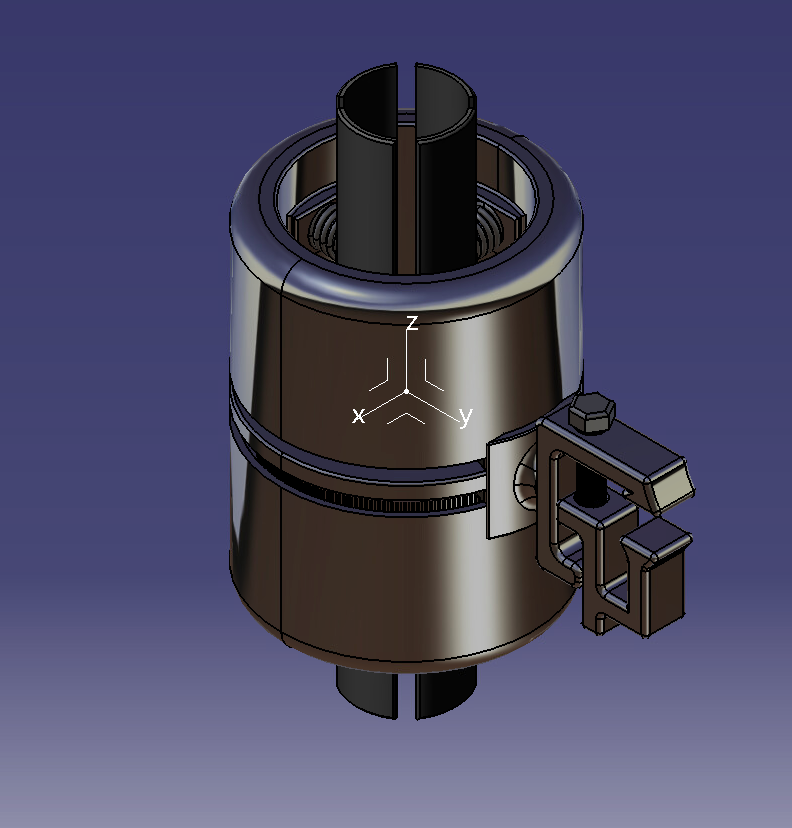

From a manufacturing standpoint, the holder will be constructed in multiple parts for

assembly. The main body, particularly the cylindrical part, will be manufactured separately,

while clamps will be integrated during assembly. Rubber padding will either be integrated

into the design with specific dimensions or applied during assembly.

bottle holder must withstand the weight of a water bottle without breaking. It should

securely attach to both vertical and horizontal surfaces, with reinforced connection points

between clamps and the bottle to support weight. An adjustable design is necessary to

accommodate various bottle sizes.

From a manufacturing standpoint, the holder will be constructed in multiple parts for

assembly. The main body, particularly the cylindrical part, will be manufactured separately,

while clamps will be integrated during assembly. Rubber padding will either be integrated

into the design with specific dimensions or applied during assembly.

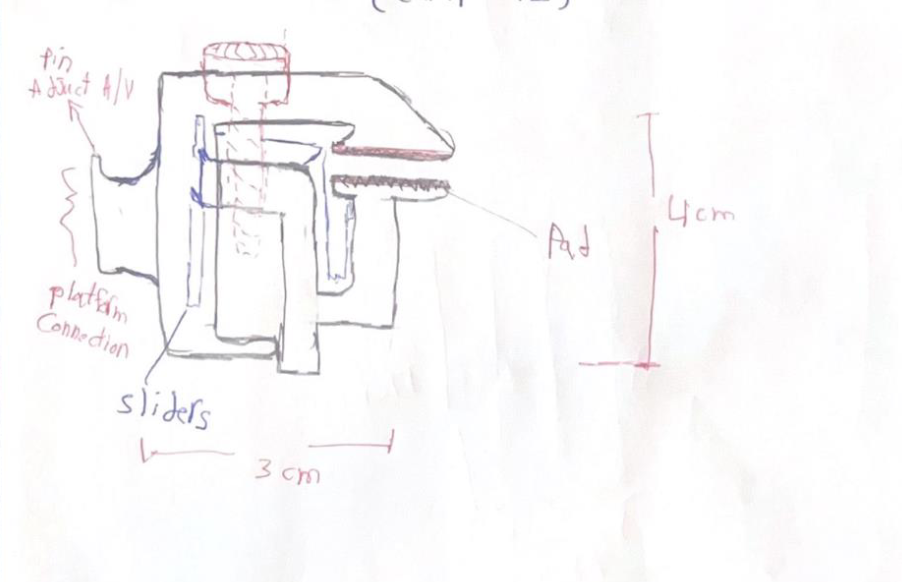

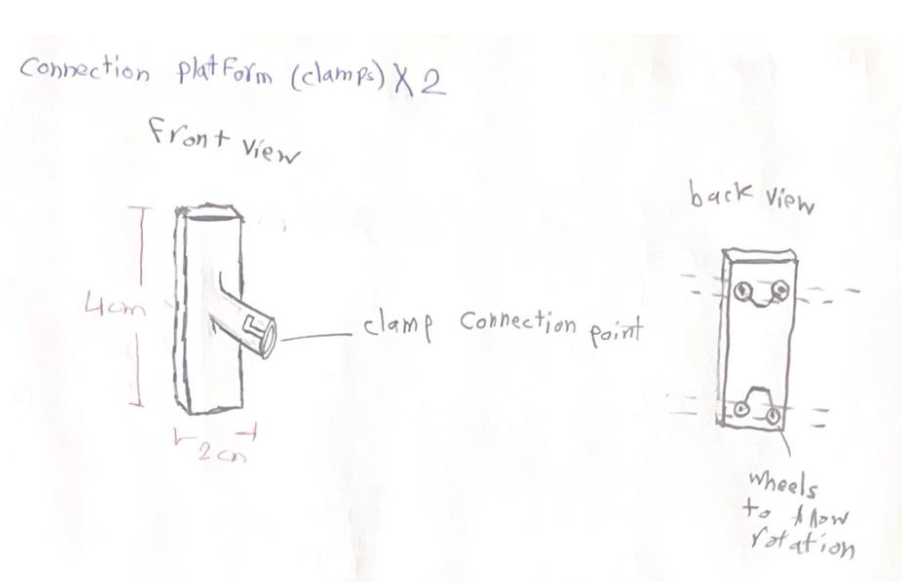

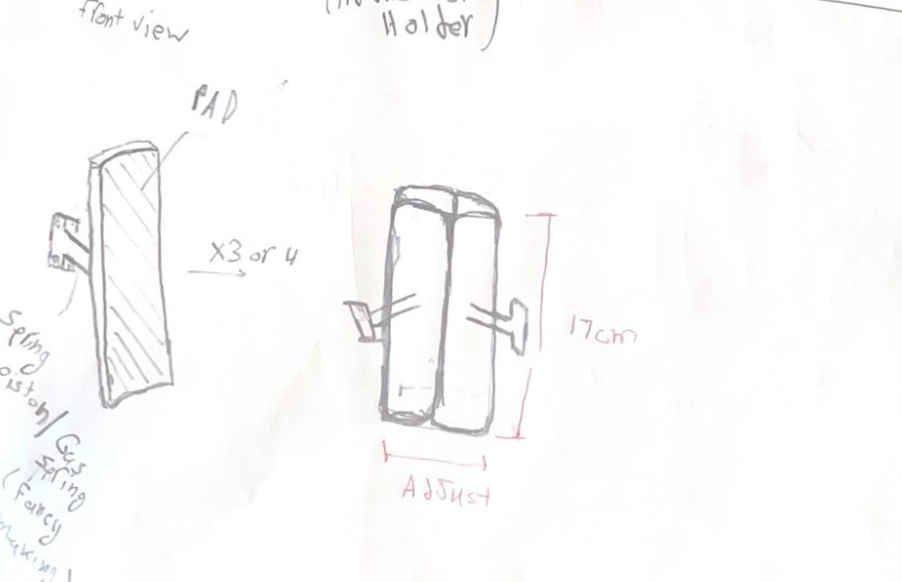

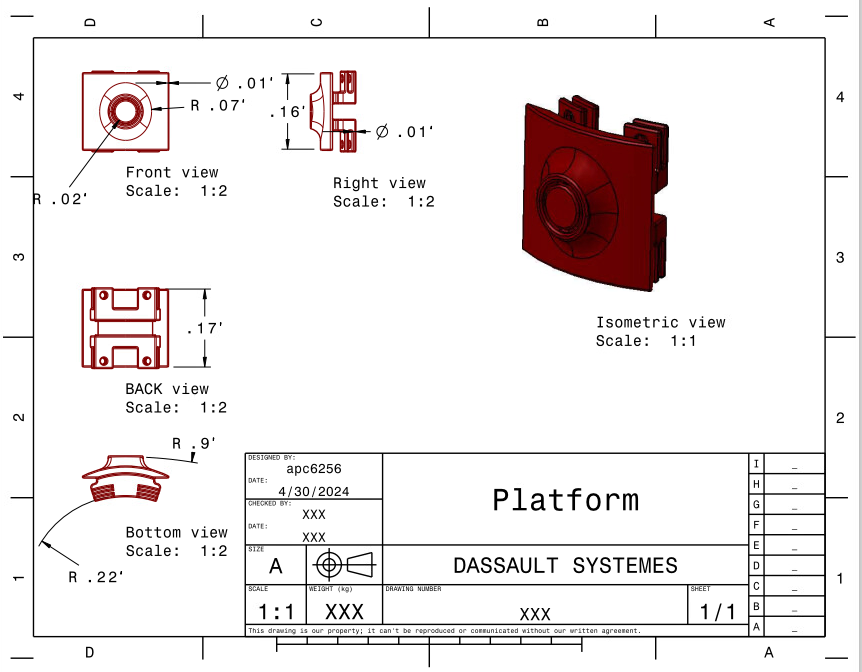

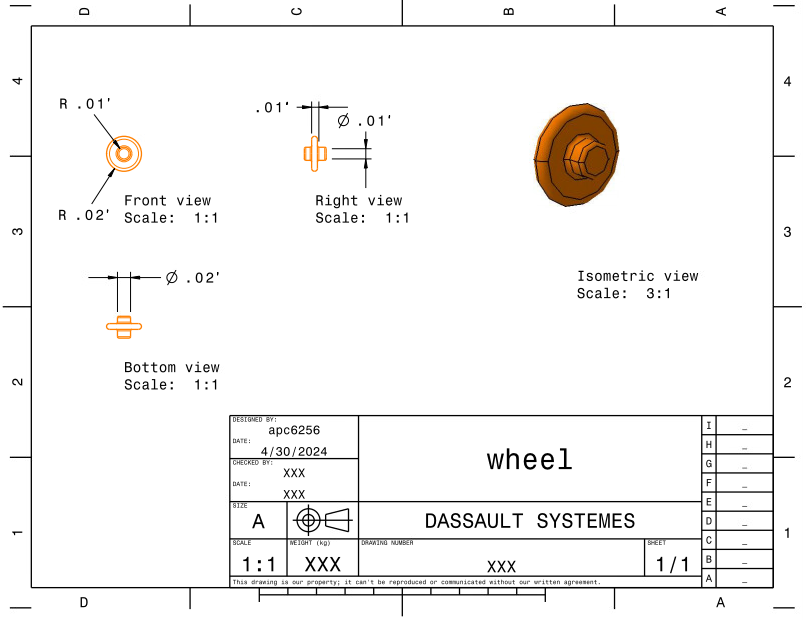

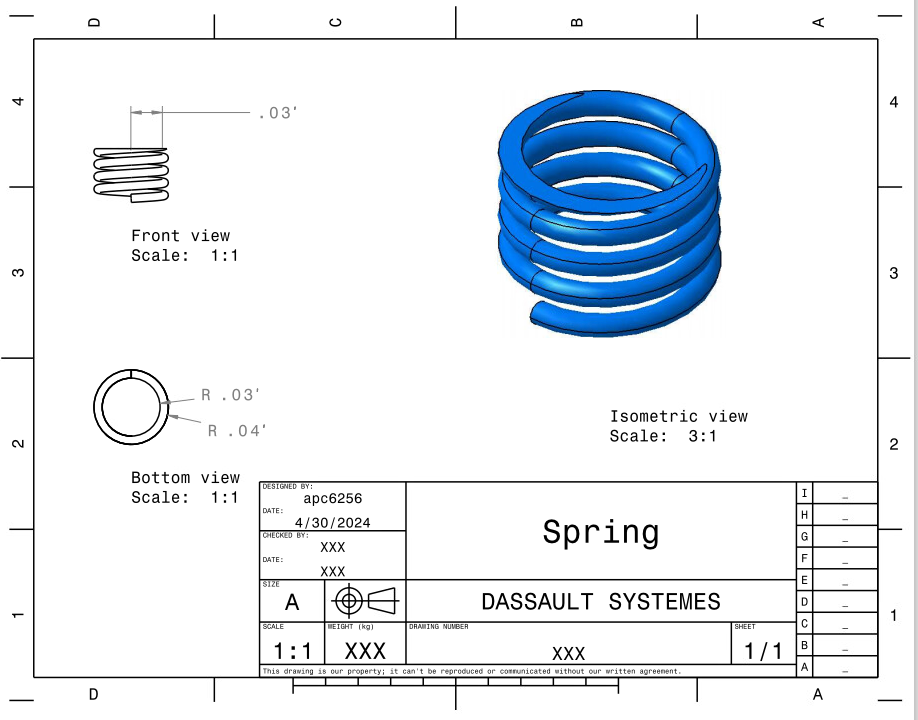

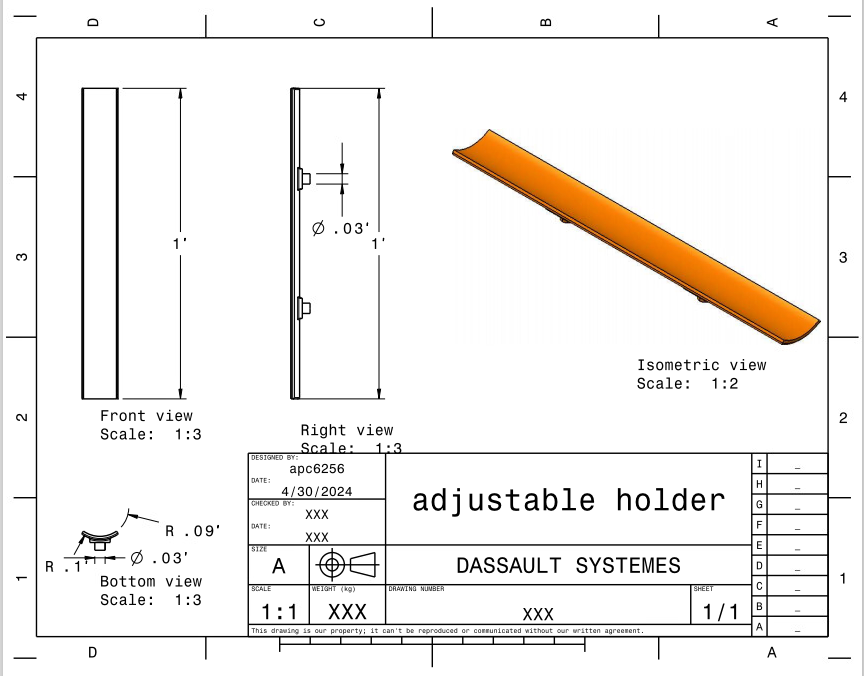

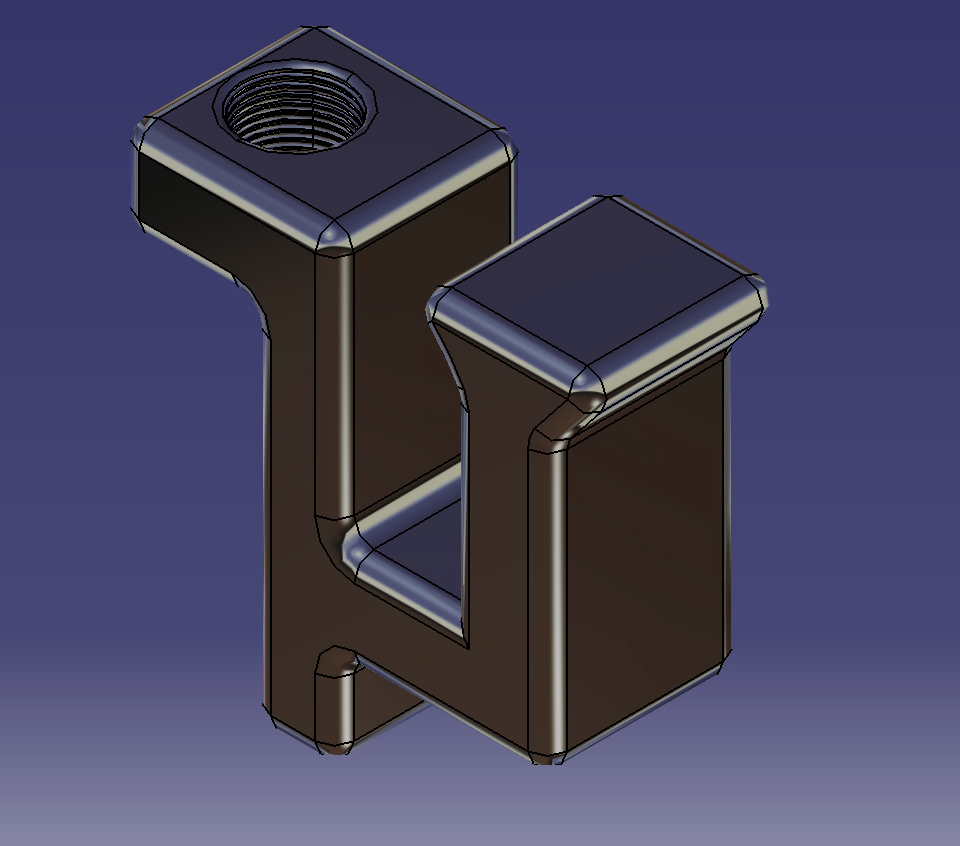

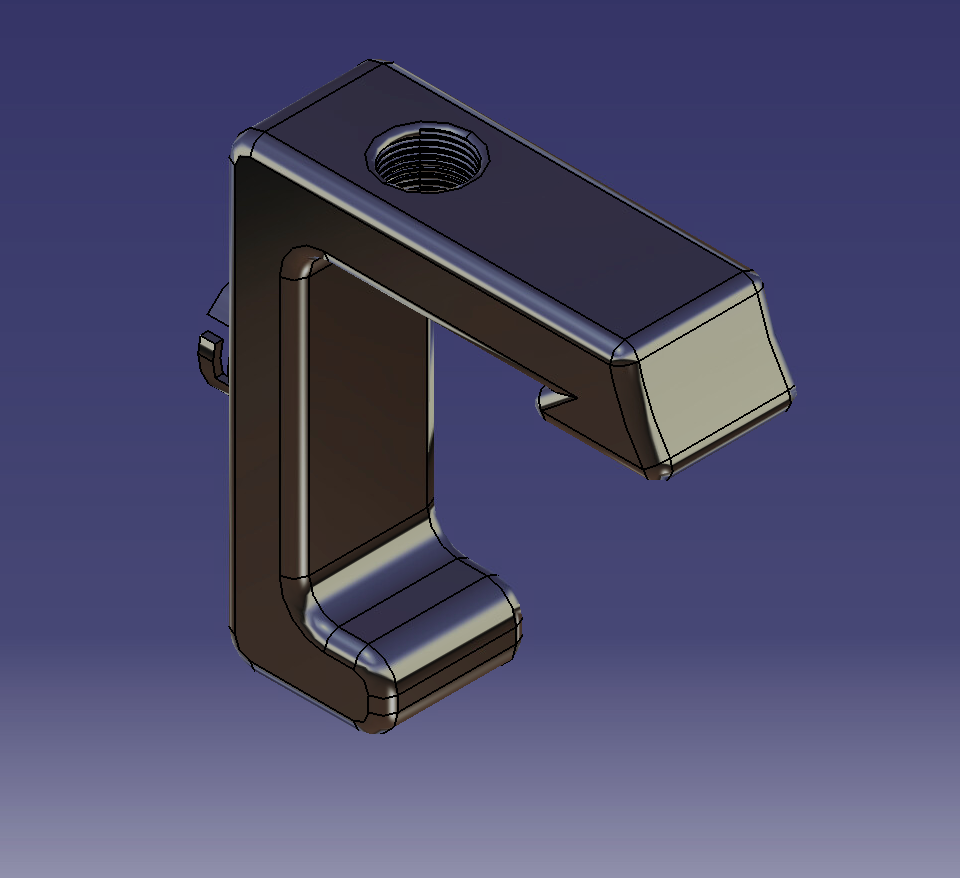

Parts Drawing & Dimensions

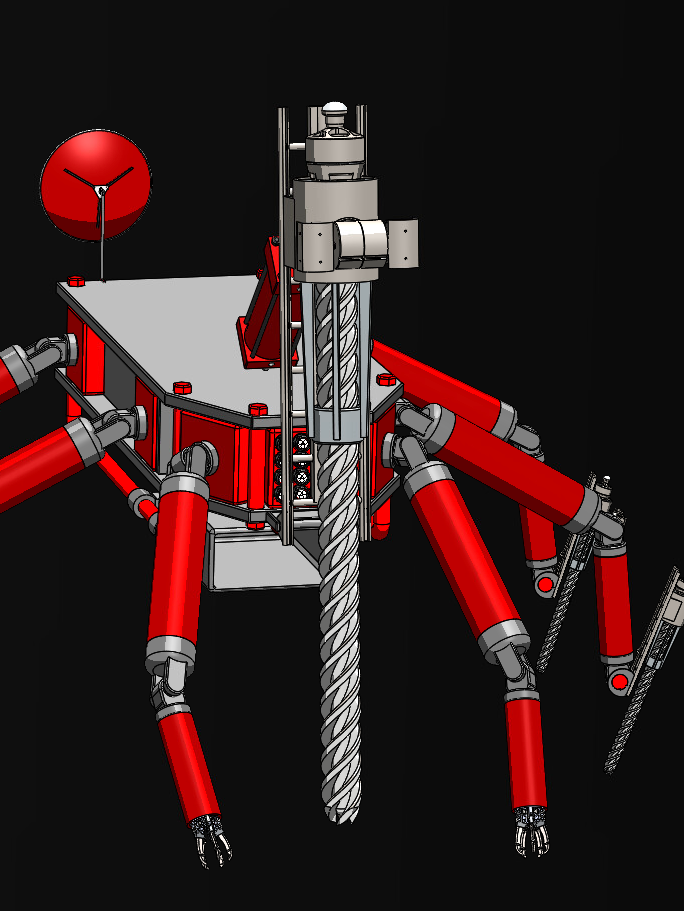

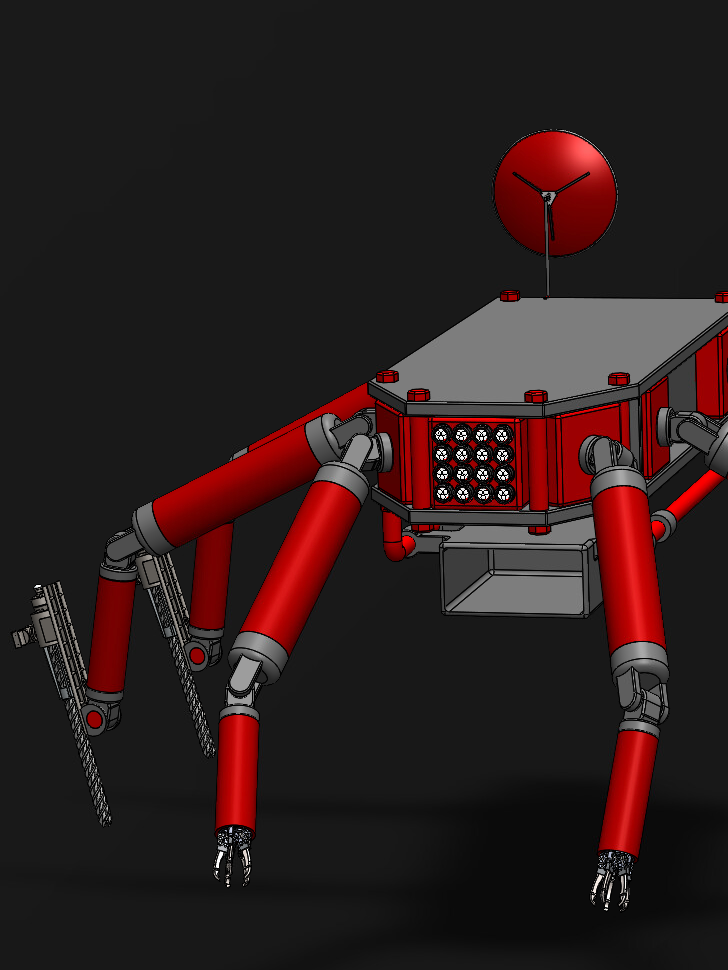

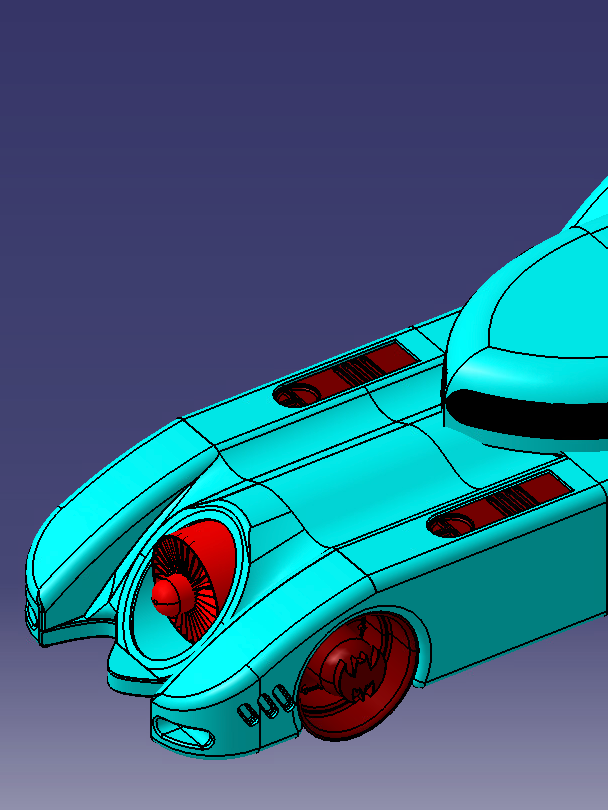

CAD Parts

Lower part of the Clamp upper part of the Clamp

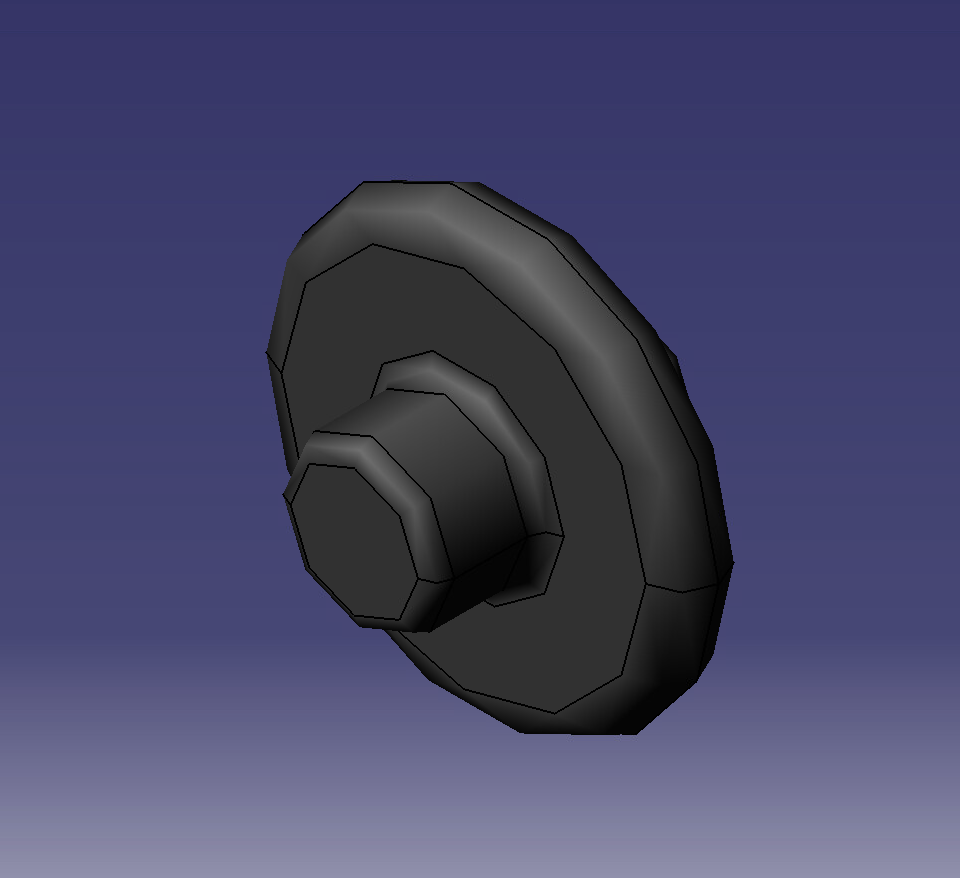

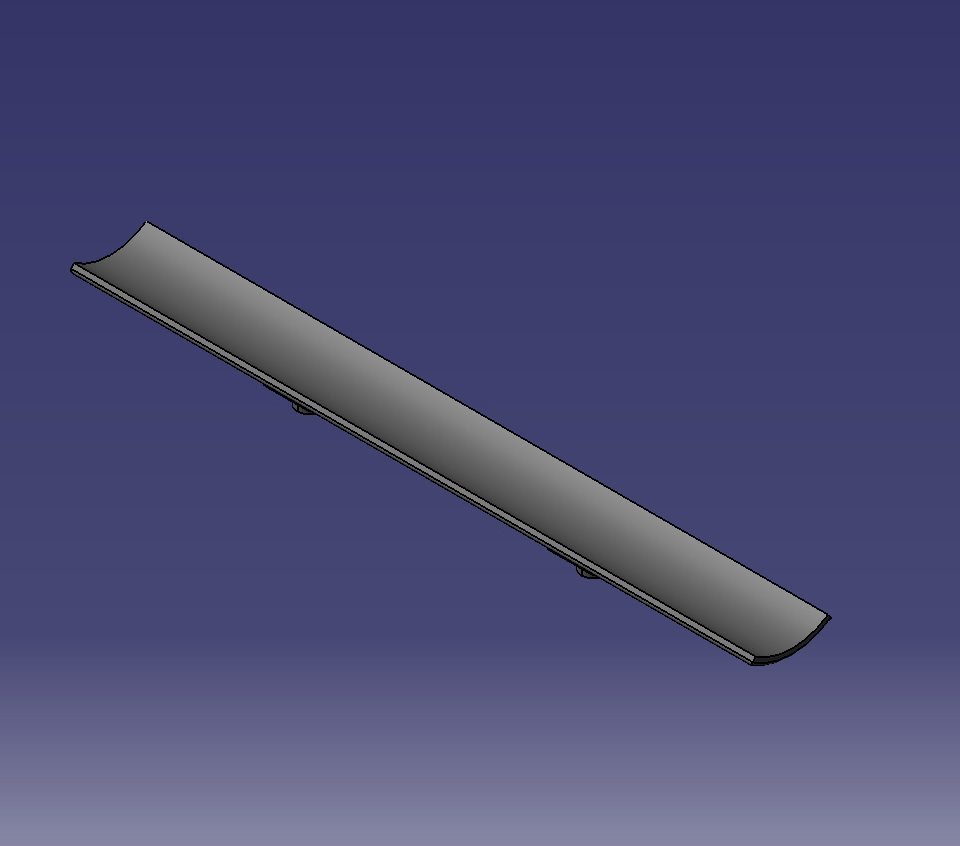

Clamp tightening screw. Vertically and horizontally adjustable platform

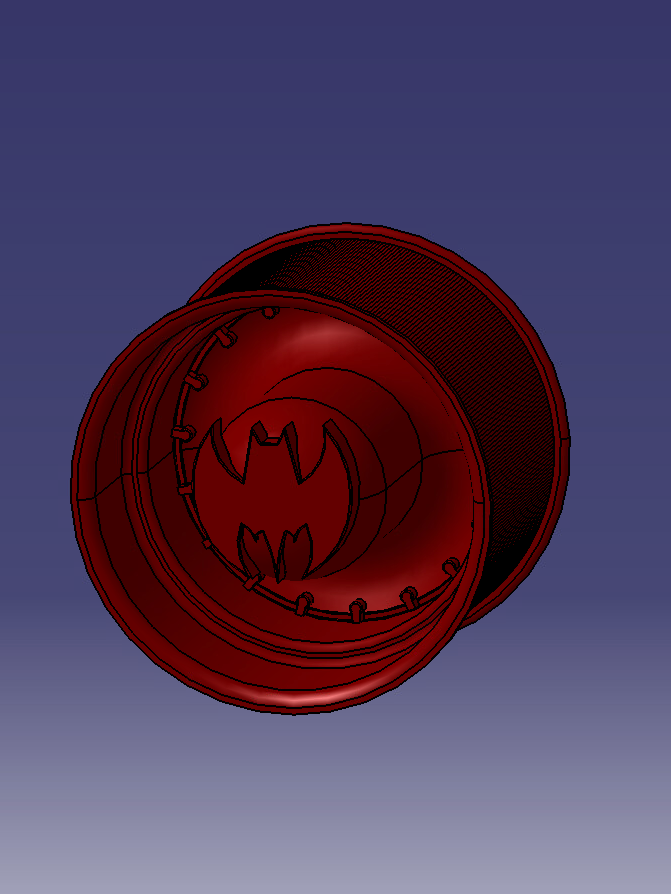

Wheel Outside Holder

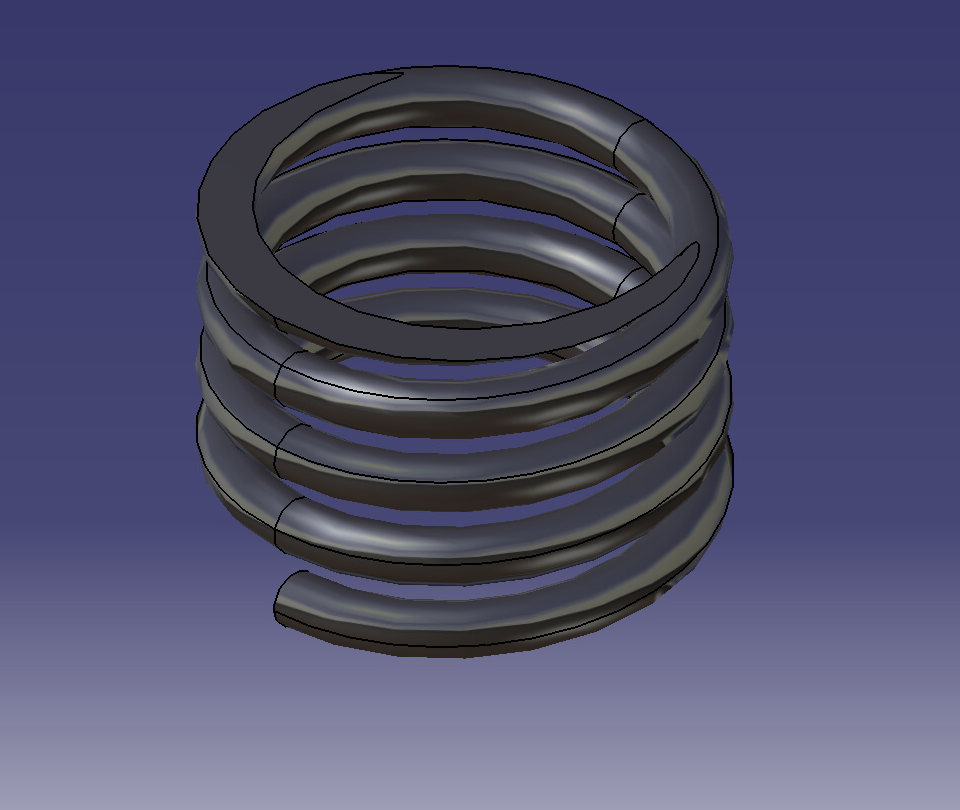

Spring Inside Holder

Final assembly

FEA

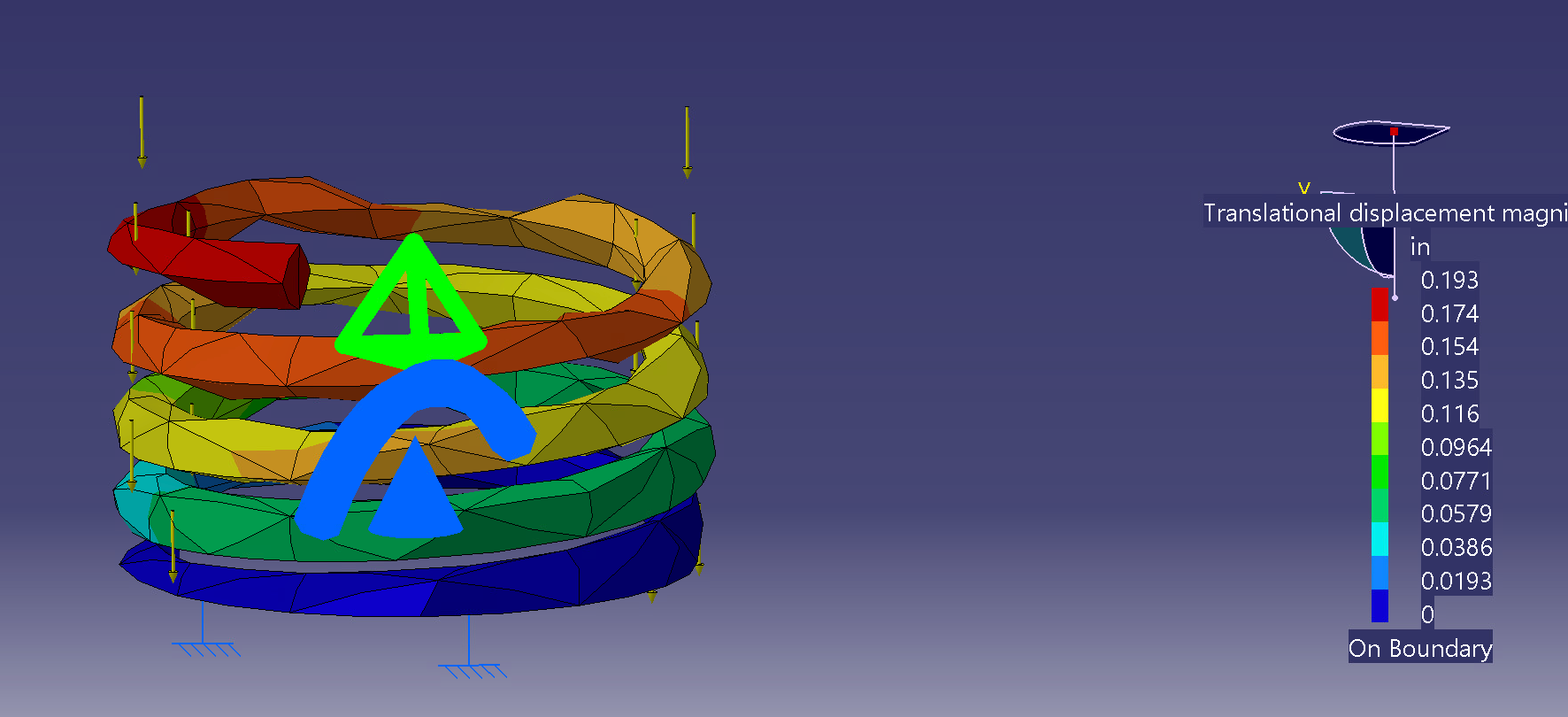

I subjected each component to what I deemed its maximum

stress level: each spring endured a 20lbs force, ensuring that even with the weight of the water

bottle, permanent deformation of the springs was improbable, thereby maintaining their ability

to secure the bottle in place.

stress level: each spring endured a 20lbs force, ensuring that even with the weight of the water

bottle, permanent deformation of the springs was improbable, thereby maintaining their ability

to secure the bottle in place.

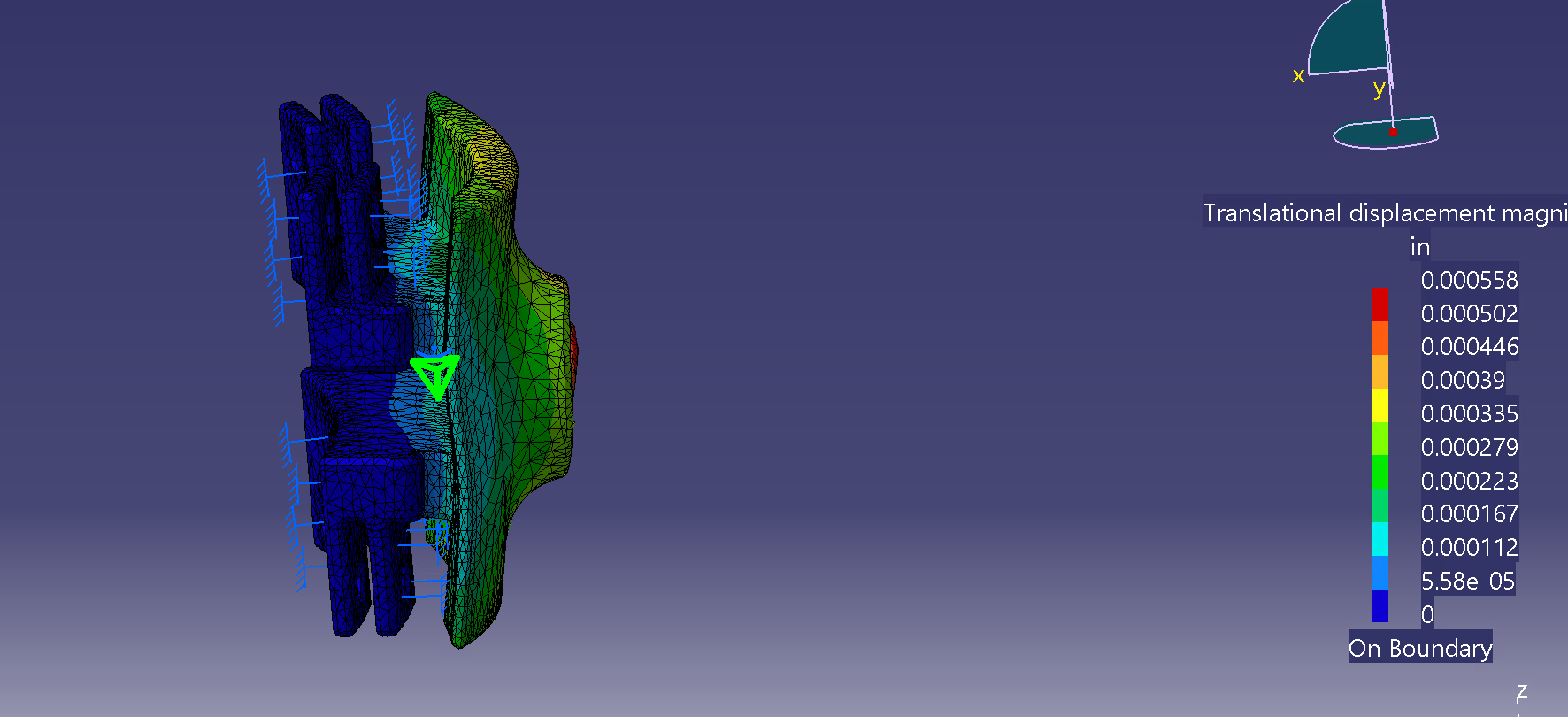

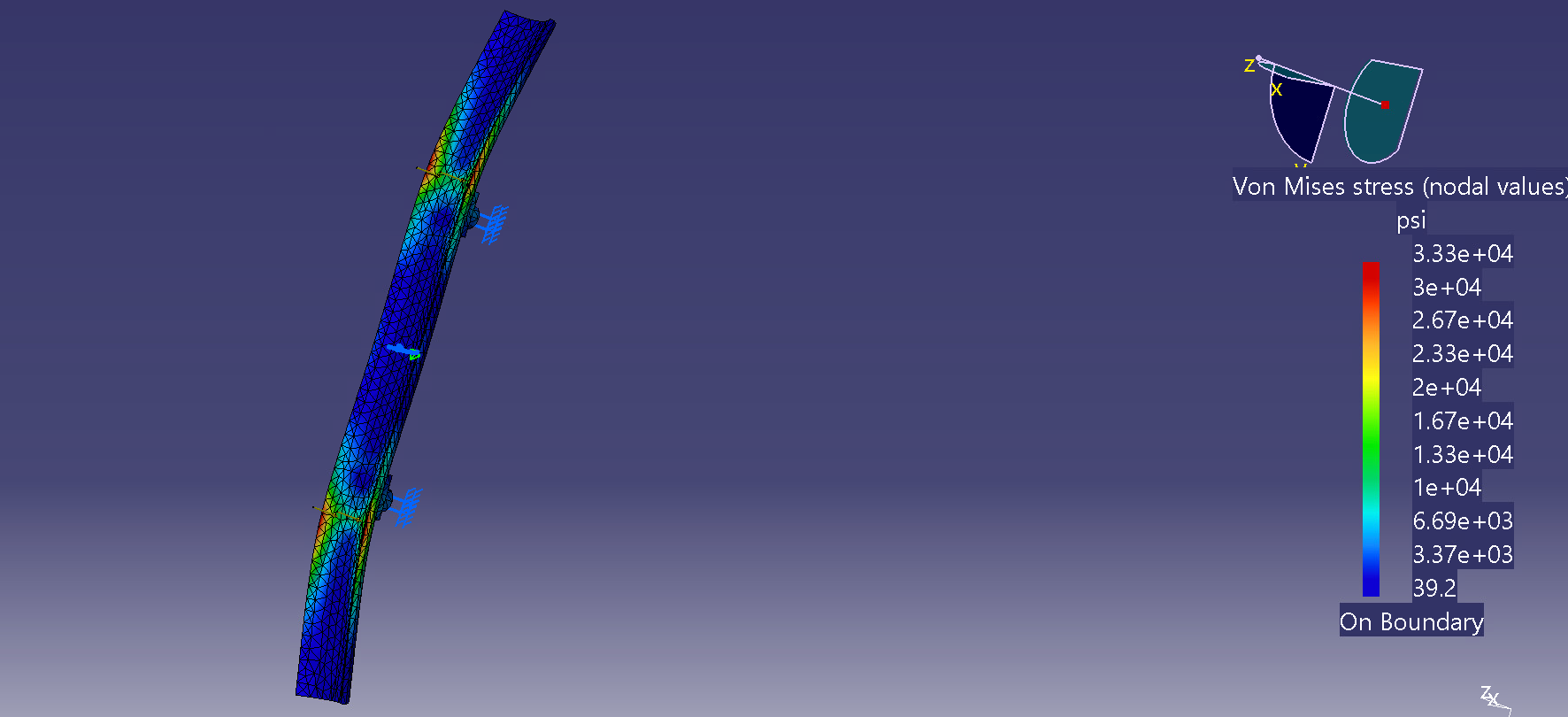

To simulate its placement within the assembly, the platform was clamped accordingly and

subjected to a 500lbs force at the anticipated connection point. This force threshold was

chosen as it exceeds any expected external force the platform might encounter, ensuring its

stability under various conditions. Additionally, the plastic interior holder endured significant

force, demonstrating its resilience against anticipated stresses and twists.

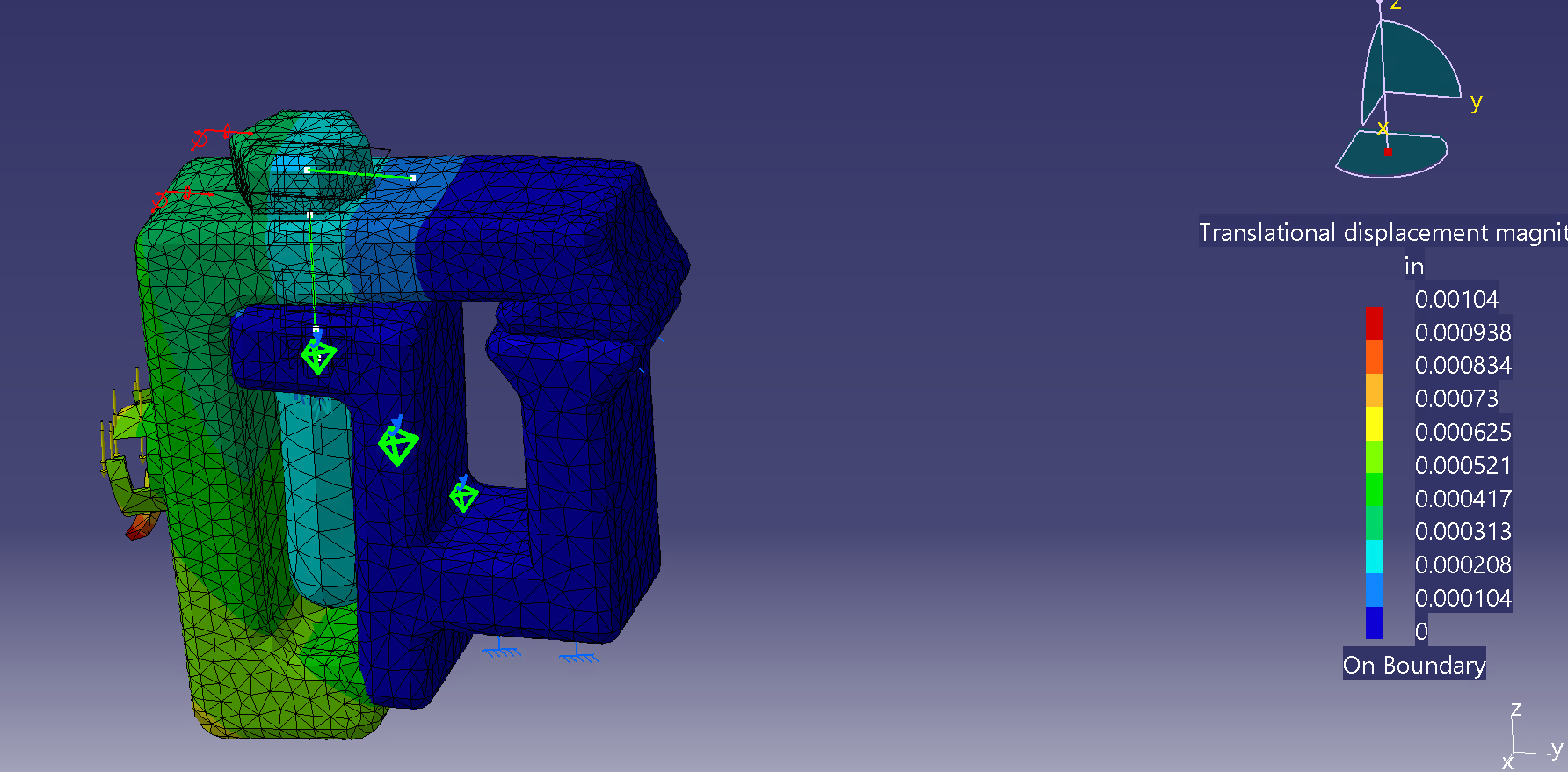

Simulations also incorporated the main clamp, with forces applied near the spring piston to

evaluate its performance under operational conditions.